Xanthan gum, also known as Hansheng gum, is a widely used microbial extracellular polysaccharide produced by Xanthomonas campestris using carbohydrates as the main raw material (such as corn starch) through fermentation engineering. It has unique rheological properties, good water solubility, thermal and acid-base stability, and good compatibility with various salts. As a thickener, suspension agent, emulsifier, and stabilizer, it can be widely used in more than 20 industries such as food, petroleum, and medicine. It is currently the largest and most widely used microbial polysaccharide in the world.

Xanthan Gum For Sale

-

DHV Xanthan GumDHV Xanthan Gum is high viscosity dispersible xanthan gum biopolymer that gives high viscosity build at low shear rates. It can be utilized as a viscosifier in oilfield drilling, workover, and complet...LEARN MORE

-

F80 Xanthan GumF80 Xanthan Gum is regular powder transparent grade xanthan gum produced by fermentation of corn starch and beans protein with Xanthomonas campestris; its solutions are neutral.LEARN MORE

-

F200 Xanthan GumF200 Xanthan Gum is a fine powder xanthan gum produced by fermentation of corn starch and beans protein with Xanthomonas campestris, its solutions are neutral.LEARN MORE

-

FT Xanthan GumFT Xanthan Gum is highly transparent, smooth and soluble, has good viscoelasticity, and its rheology meets the food rheology requirements for safe swallowing, ensuring that food with low viscosity is ...LEARN MORE

-

HD Xanthan GumHD Xanthan Gum is a kind of compound food additive processed by Xanthan Gum and maltodextrin, with characteristics of fast dispersion, excellent hydration ability, and theology. Because of its charact...LEARN MORE

-

HV Xanthan GumHV Xanthan Gum is high viscosity industrial xanthan gum biopolymer that gives high viscosity build at low shear rates. It can be utilized as a viscosifier in oilfield drilling, workover, and completio...LEARN MORE

-

KF Xanthan GumKF Xanthan Gum can dissolve quickly in cold and hot water; it has good thickening stability, smooth aqueous solution and good rheology, which can improve the appearance and taste of drinks. It's t...LEARN MORE

-

RD Xanthan GumRD Xanthan Gum is a xanthan gum with rapid dispersion and hydration ability prepared by fermentation and extraction of starch by Xanthomonas. With good rheology and shear resistance, it is a polymer h...LEARN MORE

Structure

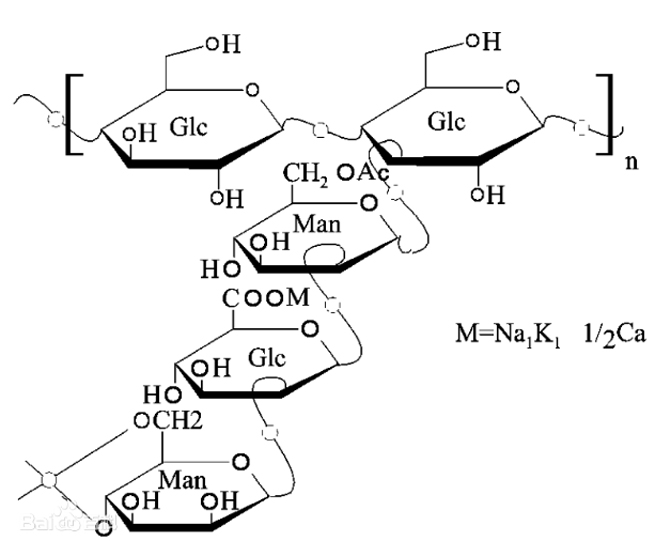

Xanthan gum, also known as xanthan gum or Hansheng gum, is an extracellular acidic heteropolysaccharide produced by fermentation of Xanthomonas flavus. It is a polysaccharide polymer compound composed of D-glucose, D-mannose, and D-glucuronic acid in a ratio of 2:2:1, with a relative molecular weight of over 1 million. The secondary structure of xanthan gum is the reverse winding of the side chains around the main chain skeleton, which is maintained by hydrogen bonding to form a rod-shaped double helix structure.

Character

Xanthan gum is a light yellow to white flowable powder with a slight odor. Easy to dissolve in cold and hot water, neutral solution, resistant to freezing and thawing, insoluble in ethanol. Disperse and emulsify in water to form a stable hydrophilic viscous colloid. [2]

Performance Characteristics

Xanthan gum is currently the most superior biological gum in the world, which integrates thickening, suspension, emulsification, and stability. The amount of pyruvate groups at the end of the molecular side chains of xanthan gum has a significant impact on its properties. Xanthan gum has the general properties of long-chain polymers, but it contains more functional groups than general polymers and exhibits unique properties under specific conditions. Its conformation in aqueous solution is diverse, and it exhibits different characteristics under different conditions.

1. Suspension and emulsification properties

Xanthan gum has a good suspension effect on insoluble solids and oil droplets. The molecules of xanthan gum sol can form super bound helical copolymers, forming a fragile gel like network structure, which can support the morphology of solid particles, droplets, and bubbles, demonstrating strong emulsification stability and high suspension ability.

2. Good water solubility

Xanthan gum can dissolve quickly in water and has good water solubility. Especially soluble in cold water, it eliminates the need for complicated processing and is convenient to use. However, due to its strong hydrophilicity, if water is added directly without sufficient stirring, the outer layer will absorb water and expand into micelles, which will prevent water from entering the inner layer and affect its effectiveness. Therefore, it is necessary to pay attention to correct use. Yellow gum dry powder or mixed with salt, sugar, and other dry powder excipients, slowly add the stirring water to make a solution for use.

3. Thickening properties

Xanthan gum solution has the characteristic of low concentration and high viscosity (the viscosity of a 1% aqueous solution is 100 times that of gelatin), making it an efficient thickener.

4. Pseudo plasticity

Xanthan gum aqueous solution exhibits high viscosity under static or low shear conditions, and exhibits a sharp decrease in viscosity under high shear conditions, while the molecular structure remains unchanged. When the shear force is eliminated, the original viscosity is immediately restored. The relationship between shear force and viscosity is completely plastic. Xanthan gum exhibits outstanding pseudoplasticity, which is highly effective in stabilizing suspensions and emulsions.

5. Stability to heat

The viscosity of xanthan gum solution does not change significantly with temperature changes. Generally, polysaccharides undergo viscosity changes due to heating, but the viscosity of xanthan gum aqueous solution remains almost unchanged between 10-80 ℃. Even low concentration aqueous solutions exhibit stable high viscosity over a wide temperature range. 1% xanthan gum solution (containing 1% potassium chloride) was heated from 25 ℃ to 120 ℃. Its viscosity only decreased by 3%.

6. Stability of acidity and alkalinity

Xanthan gum solution is very stable to acidity and alkalinity, and its viscosity is not affected between pH 5-10. There is a slight change in viscosity when pH is less than 4 and greater than 11. Within the range of PH3-11, the maximum viscosity is within 10% of the minimum value. Xanthan gum can dissolve in various acid solutions, such as 5% sulfuric acid, 5% nitric acid, 5% acetic acid, 10% hydrochloric acid, and 25% phosphoric acid. These xanthan gum acid solutions are quite stable at room temperature and the quality of the product remains unchanged for several months. Xanthan gum can also dissolve in sodium hydroxide solution and has thickening properties. The resulting solution is very stable at room temperature. Xanthan gum can be degraded by strong oxidants such as perchloric acid and persulfuric acid, and the degradation accelerates with increasing temperature.

7. Stability of salt

Xanthan gum solution can be mixed with many salt solutions (potassium salts, sodium salts, calcium salts, magnesium salts, etc.), and its viscosity is not affected. Under high salt concentration conditions, even in saturated salt solutions, its solubility is maintained without precipitation and flocculation, and its viscosity is almost unaffected.

8. Stability of enzymatic hydrolysis reaction

The stable double helix structure of xanthan gum endows it with strong antioxidant and anti enzymatic abilities. Many enzymes such as proteases, amylases, cellulases, and hemicellulases cannot degrade xanthan gum.

Main Uses

Due to its unique properties, xanthan gum has an extremely wide range of applications in more than ten fields such as food, petroleum, medicine, and daily chemical industry. Its high degree of commercialization and wide range of applications make it unmatched by any other microbial polysaccharide.

1. In terms of food, many foods add xanthan gum as a stabilizer, emulsifier, suspension agent, thickener, and processing aid. Xanthan gum can control the rheology, structure, flavor, and appearance of products, and its pseudo plasticity can ensure good taste. Therefore, it is widely used in salad dressings, bread, dairy products, frozen foods, beverages, seasonings, brewing, candies, pastries, soups, and canned foods. In recent years, people in more developed countries have often been concerned about the high calorific value in food, which can lead to weight gain. Xanthan gum has dispelled this concern because it cannot be directly degraded by the human body. In addition, according to a report from Japan in 1985, a comparative test was conducted on eleven food additives, and xanthan gum was the most effective anticancer agent among them.

2. In terms of daily chemical industry: Xanthan gum molecules contain a large number of hydrophilic groups, making it a good surfactant with antioxidant and anti-aging effects. Therefore, almost the vast majority of high-end cosmetics use xanthan gum as its main functional component. In addition, xanthan gum can also be used as an ingredient in toothpaste to substantially thicken and shape, reducing tooth surface wear.

3. In terms of medicine, xanthan gum is a functional component in the currently popular microcapsule drug capsule materials internationally, playing an important role in controlling drug release; Due to its strong hydrophilicity and water retention, it has many specific medical applications, such as forming a dense water film to avoid skin infections; Reduce thirst in patients after radiation therapy. In addition, Li Xin and Xu Lei have written articles pointing out that xanthan gum itself has a significant enhancing effect on the humoral immune function of mice.

4. Application in industry and agriculture: In the petroleum industry, due to its strong pseudoplasticity, a low concentration of xanthan gum (0.5%) aqueous solution can maintain the viscosity of drilling fluid and control its rheological properties. Therefore, the viscosity is extremely low at the high-speed rotating drill bit, saving power; However, high viscosity is maintained in the relatively stationary drilling area to prevent wellbore collapse. And due to its excellent salt resistance and heat resistance, it is widely used in drilling in special environments such as oceans and high salt zones, and can be used as an oil recovery and displacement agent to reduce dead oil zones and improve oil recovery rates.

-

Application of Resistant Dextrin Powder in FoodMar 29, 2025

-

Effects and Functions of Maltitol CrystalsMar 22, 2025

+86-531-69959201

sales@saigaonutri.com

No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China